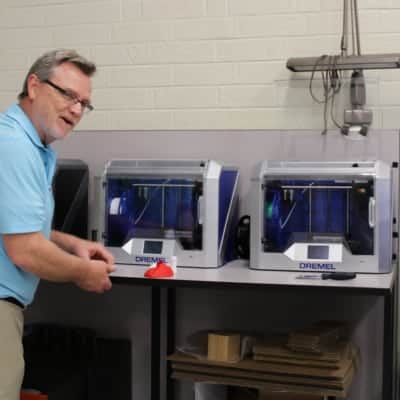

Inside McDowell Technical Community College’s (MTCC) Universal Advanced Manufacturing Center is an 8,000 square-foot facility housing the college’s machining program. The space is outfitted with CNC machines, manual machines, new 3D printers, and computers loaded with Fusion 360 for product design.

Seventeen-year-old Blaine Williams stood over a manual lathe machine — a device that cuts cylinder shapes — making adjustments to a metal part.

“You know what a BMX bike is?” he asked while explaining what the machine could be used for. “You know the little pedals that they step their feet on that screw into the axle? That would be something right there.”

While Williams isn’t going into the BMX bike-making industry, he said he’s always liked machining and started taking classes as a high school student in the Career and College Promise program.

“I do a little bit of welding, and then I do this stuff,” Williams said. “It’s just more technical. It’s a challenge, and I enjoy a challenge.”

Williams’ main career pathway is Emergency Management (fire fighting, in particular), but he continues to take machining courses for the exposure.

“I go to classes at the high school,” he said. “So I do my English and my history, and then I get to come here, and it’s real world stuff. … So if I do decide to get a job doing this machining, I’m already a step ahead.”

Classmate Nathaniel McEntire is also taking machining courses as a side interest, but one that will support his career path in auto body. He said if did follow in his father’s footsteps (who has been a machinist for 20 years), he felt confident in his ability to run a machine through his classes at MTCC and would consider an associate degree.

“I can go to a plant and get a job almost instantly. Marion, Asheville, anywhere,” he said of the need for machinists.

Although the path to a job through machining is clear, McEntire said learning machining isn’t without its challenges. One of the hardest aspects, he said, is all the decimals and fractions you have to memorize to use the machines.

“Numbers are everywhere,” said Instructor Wayne Stines, who has been teaching at McDowell Tech for 19 years. “I emphasize that if you’re going to be a part of manufacturing and especially supporting manufacturing through machining, then you need to pay attention to your math. You need to be able to add, subtract, multiply, and divide whole numbers, common fractions, decimal fractions, and know a good handful to a dozen shop formulas to get you in and out of the processes of each machine.”

Depending on how in-depth students would like to go in the field, McDowell Tech offers three different degree programs in computer integrated machining, including an associate degree, a diploma, and a certificate.

The college also has several partnerships with local industry, even bringing companies in to see classes and students. Industry partnerships include ABB, Marion Machine, Carriage House Door, Haldex, RDM Industrial Electronics, and more.

“We articulate with the high school. We articulate pretty much anything that industry needs,” Stines said.

“It’s very important,” Stines said of the college’s collaboration with local industry. “There’s a great demand for machinists in this area. You can’t compare it to Spartanburg or Asheville. We’re our own nestled region in the mountains, and we embrace that. We embrace the children that are coming out of the high school and trying to get them interested.”

Ultimately, Stines said it is the students that have kept him teaching at McDowell Tech for so long — and driving in to Marion 63 miles one-way from Henderson County.

“It’s so gratifying to see the success of a student from the time they walk in until they graduate,” he said. “It’s so gratifying to teach a skill that can save somebody’s life, literally, and get them straight on a path of success in their life, with a career, with a skill. It’s a wonderful feeling.”

Interested in more STEM education news? Sign up for our STEM newsletter here.